The Factory

The main factory covers an indoor surface area of approximately 3,000 square metres, plus an outside area of approximately 10,000 square metres. The building is divided into a number of bays served by overhead travelling cranes that can support loads weighing up to 6.3 tons.

Cosmel occupies a strategic position close to the “Cuggiono Nord” junction on the SS.336, 10 minutes from Milan Malpensa airport (MXP) and from the main motorways in the North West of the country (A4, A8 and A9).

Machinery

Lathes

12

Total

5

Large horizontal

Maximum dimensions

1000 x 3300 [mm]

4

Small

Maximum dimensions

400 x 1000 [mm]

3

Large vertical

Maximum dimensions

1350 x 1000 [mm]

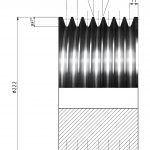

Deep Drilling

2

Drillers

- 6/7 m maximum depth

240 mm hole dimensions

also operates on square bars - 5 m maximum depth

5-65 mm hole dimensions

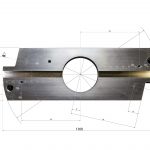

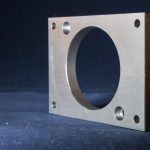

Work centres

3

Horizontal

Maximum dimensions

2100x 1500y 1500z [mm]

6

Vertical

Maximum dimensions

1200 x 800 y 700 z [mm]

Control

- 3D measurement machine (900 cube, class 1 certificate)

- Resetting bench (L up to 1,500 mm)

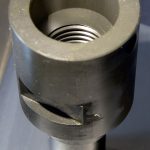

Other processing

The company can in any case handle finished components, including any treatments, such as:

- Tempering

- Nitriding

- Nickel plating

- Chrome plating

Would like further details about the company’s machinery? Please write to info@cosmel.it or enter your email here below.